|

"Canaanean Blades

and the associated Tabular Scrapers are a very characteristic Early

Bronze Age artifact and were widely traded throughout the Middle East.

The blades are noted for their size, regularity, and high degree of

technical skill indicated."--------1992,

Eugene M. Futato, "Personal communication."

"Canaanean blades and sickle segments are a widespread

and characteristic artifact of the Early Bronze Age in the southern

Levant."--------1996,

Eugene M. Futato, "Early Bronze III Canaanean Blade/Scraper Cores

From Tell Halif, Israel," Retrieving The Past, Essays On

Archaeological Research And Methodology In Honor Of Gus W. Van Beek,

p. 61.

"Levant----The

regions on the eastern Mediterranean and the Aegean, from Greece to

Egypt------."------1979,

Noah Webster, "Webster's Deluxe Unabridged Dictionary,"

p. 1040.

"The most

unusual aspect of the Canaanean blade technology at Tell Halif (in

Israel) is there is no evidence for

preliminary flaking of the faces of the blade cores. These faces do not

appear to have been prepared."--------1996,

Eugene M. Futato, "Early Bronze III Canaanean Blade/Scraper Cores

From Tell Halif, Israel," Retrieving The Past, Essays On

Archaeological Research And Methodology In Honor Of Gus W. Van Beek,

p. 66.

"We

presume that actual blade preparation was done by indirect percussion,

using a punch. Controlling the precise point of application and

direction of force is critical in removing long, thin blades from a core."----1996,

Eugene M. Futato, "Early Bronze III Canaanean Blade/Scraper Cores

From Tell Halif, Israel," Retrieving The Past, Essays On

Archaeological Research And Methodology In Honor Of Gus W. Van Beek,

p. 67.

"Four basic technologies were used for the

manufacture of sickles (blades)

in the post-Neolithic periods"---------1997,

Steven A. Rosen, "Lithics After The Stone Age," p. 44.

"Backing on

Canaanean sickles is virtually absent. Some rare pieces seem to show a

kind of burin-blow backing but it is difficult to know if this is

intentional or the result of longitudinal breakage."---------1997,

Steven A. Rosen, "Lithics After The Stone Age," p. 48.

"Shortly

after 13,000 B.C. (in Egypt)

grinding stones and sickle blades with glossy sheen on their bits appear

in Late Paleolithic tool kits"---------1979,

Michael A. Hoffman, "Egypt Before The Pharaohs, The Prehistoric

Foundations Of Egyptian Civilization," p. 88.

"Grain and

other field crops (in Cyprus)

were harvested with sickles, a labor intensive practice. According to

Mr. Georghiou, since harvesting often was too much work for any one

family, additional workers were usually hired."--------2000,

John C. Whittaker, "The Ethnoarchaeology Of Threshing In Cyprus,"

Near Eastern Archaeology, 63:2, p. 63.

CANAANEAN SICKLE BLADES

EARLY BRONZE AGE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

Early descriptions of Canaanean blades refer to

them as "ribbon knives." The name is a reflection of their long,

straight and uniform lines. Canaanean blades are described as one of the

most important and elaborate lithic technologies of the Middle East.

They first appear in the southern Levant region of the

eastern Mediterranean during the Early Bronze Age. |

|

CLICK ON PICTURE FOR LARGER IMAGE

CANAANEAN SICKLE BLADES, UNUSED

BLADES, CORE,

TABULAR SCRAPER & BLANK

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This picture shows several examples

of Canaanean core and blade/flake production related artifacts. They were

excavated on an Early Bronze Age site in southern Israel at Tell

Halif in the southern Levant region. At top center is a core with several uniform long narrow

blade removal scars. At top left and right are two good examples of

tabular scrapers. The example on the right is described as a blank

(unused). At center left and lower left are two unused Canaanean

blades. At second row second from left is a sickle blade segment

that has sickle sheen from use. At lower right is a blade that is

described as a reaper knife and it also has sickle sheen from use.

At bottom row center is a blade that was used as a scraper and may

have been resharpened from a much larger tabular scraper. The longest blade in

this picture measures 8 3/4 inches (22.2 cm) long. |

|

|

Canaanean blades were first described and named by R.

Neuville in 1930. He coined the term Canaanean and referred to them as

"des couteaux a aretes," which translates to "edges of knives." |

|

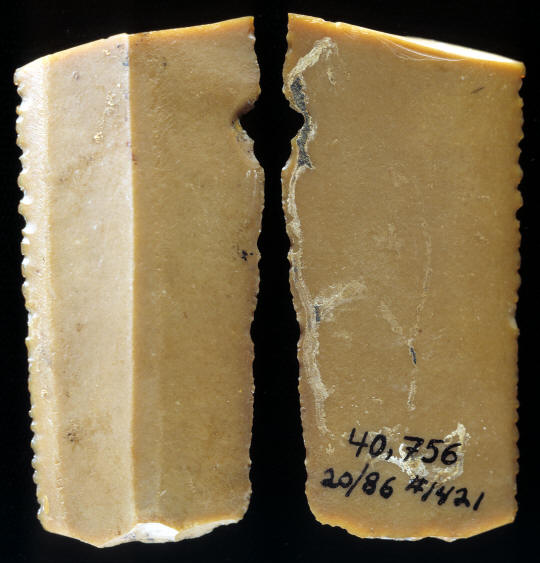

CLICK ON PICTURE FOR LARGER IMAGE

COMBINATION CANAANEAN BLADE &

TABULAR SCRAPER CORE

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This core, and other cores

from Tell Halif are most notable for their duel purpose blade/flake tool

production. They produced long narrow blades from one side of the core

and large oval tabular flakes from another side. The picture on the left

shows an area of the core where long narrow blades were uniformly

removed for the production of sickle blades and reaping knives. The

picture on the right shows an area of the core where a large oval

cortical (outer surface)

flake was removed for use as either a scraper or knife. Canaanean cores

are described as large single platform blocks that were worked on one to

three faces. Blades from Tell Halif are described as having been removed indirectly with a

punch. But Chabot and Pelegrin's analysis of hundreds of Canaanean blades

from the Tell Atij and Tell Gudeda sites in Syria, showed a high

percentage of those blades were removed by lever-pressure with the use

of a copper point. Platforms are narrow relative to the blade and often show

faceting. Unlike other post Neolithic sickle blade technologies in the

Levant region, Canaanean blade technology is known for the production of

long blades. These types of blades can be greater than 5 7/8 inches (15

cm) long and could produce multiple sickle blade segments per blade. |

|

|

The Canaanean artifacts illustrated in this report were found

during excavation on the Tell Halif site. Tell Halif is located in southern Israel along the

southwestern edge of the Judean Hills. Excavation of the site was

sponsored by The Cobb Institution Of Archaeology at Mississippi State

University. The project began in 1983 and is called the Lahav Research

Project. Eugene Futato spent four summers on the site and did the lithic

analysis. |

|

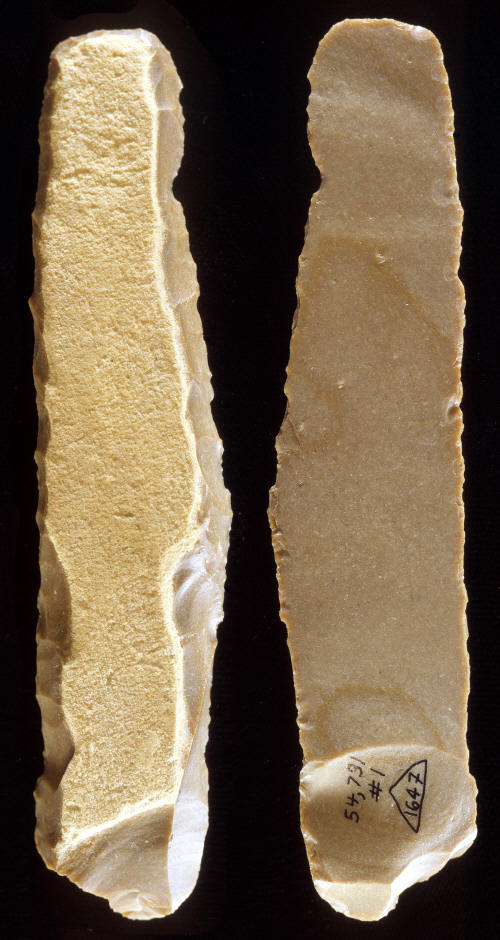

CLICK ON PICTURE FOR LARGER IMAGE

UN-USED CANAANEAN BLADE

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This is the longest

blade that was found during the Tell Halif excavation. It's actually

longer than most Canaanean blades. It's impressive for its size and also

for how flat and straight it is. Futato describes the blades from Tell

Halif as being

produced with indirect percussion, with a hammer sticking a punch. This

blade was never used. It measures 1/4 inch (6 mm) thick at the

bulb-of-percussion and 1/8 inch (3 mm) thick at the center of the blade. It also measures 1 3/16 inches (3 cm)

wide and 8 3/4 inches (22.2 cm) long. |

|

|

The Canaanean core and blade artifacts that were found

on the Tell Halif site date to the Early Bronze Age between 2500 and 2300 B.C.

The Tell Halif site also produced artifacts from the Chalcolithic era as

early as 5,500 years ago. Other periods were represented by the Late

Bronze Age, Iron Age and as recent as the Persian and Hellenistic Period

2,100 years ago. |

|

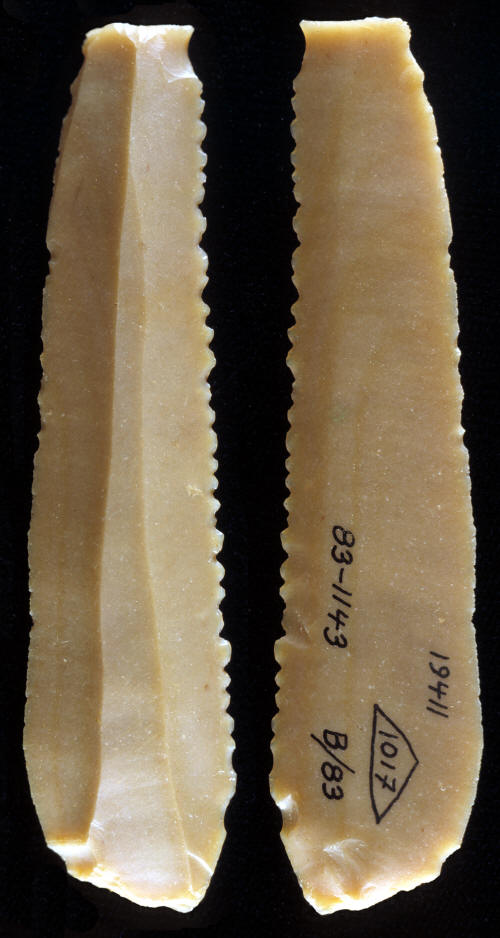

CLICK ON PICTURE FOR LARGER IMAGE

UN-USED CANAANEAN BLADE

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This unused blade was found

on the surface of a house floor in a cache along with eight other blades

and one tabular scraper. It has a "classic" Canaanean style trapezoidal cross section

that was formed by the removal of three previous blades. This blade also

has a flat profile except for a slight curve near the distal end and

fairly uniform parallel edges. The bulb-of-percussion is very thin and

is only slightly over 1/32 of an inch thicker than the rest of the

blade. This blade measures 5 3/16 inches (13.2 cm) long. |

|

|

Artifacts found during the excavation of the Tell Halif site

produced enough evidence to show that the location was a sickle blade

and tabular scraper manufacturing site. The artifacts include nine Canaanean

type cores, core fragments and other core manufacturing debris. Plus

un-utilized Canaanean blades and blades that had been modified and used

as tools. |

|

CLICK ON PICTURE FOR LARGER IMAGE

CANAANEAN SICKLE BLADE STRIKING

PLATFORM & BULB-OF-PERCUSSION

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This picture shows a

close-up view of the proximal end of the previously described blade. The

striking platform is still intact. Several of the nine blades that were

found together in a cache with this blade are reported to have retained

their striking platforms. Prepared striking platforms were placed over

the raised edges of previously removed blades. The thickest part of a

blade is located where the blade was struck from the core at the bulb of

percussion. This blade is very thin at the bulb of percussion and

measures only slightly thicker than the rest of the blade. The

percussion bulb measures 7/32 inch thick and the thickest area of the

blade measures 6/32 of an inch thick. |

|

|

Canaanean cores and blades were made from high quality

flint or chert. The material is identified by Rosen (1997) as a fine

grained Eocene flint. He reports that the majority of Canaanean blades

that have been found in the southern Levant are made of this material.

The colors range from chocolate, brown, to sometimes banded flint. |

|

CLICK ON PICTURE FOR LARGER IMAGE

CANAANEAN BLADE REAPING KNIFE

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This Canaanean

blade from Tell Halif is described as a reaping knife, as opposed to a

sickle blade segment. Sickle blade segments were made by snapping short

segments from longer blades. Reaping knives are intact blades and were

used without modification. It's believed that sickle blade segments were

hafted onto a curved crescent shaped handle and reaping knives were

hafted in a straight line. This reaping knife has a glossy silica

coating on its serrated cutting edge indicating it was probably used to

harvest some type of plant materials. |

|

|

Some of the

cores from Tell Halif are most notable for their duel purpose. Long

narrow blades were removed from one side of a core

and large oval tabular flakes from another side. Canaanean cores are

described as large single platform blocks that were worked on one to

three faces. |

|

CLICK ON PICTURE FOR LARGER IMAGE

SERRATED EDGE OF A CANAANEAN

REAPING KNIFE

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This picture shows a close up view of a portion of the cutting edge

of the previously described reaping knife. The edge has a sickle

sheen silica polish from cutting plants. |

|

|

Futato describes the Tell Halif Canaanean blades as having

been produced by indirect percussion with the use of a punch. But,

Chabot and Pelegrin's analysis of hundreds of Canaanean blades

from the Tell Atij and Tell Gudeda sites in Syria, showed a high

percentage of those blades were removed by lever-pressure with the use

of a copper point. But they also note that a substantial fraction of

them were also detached by indirect percussion (punch flaking). Their

research showed that Canaanean flint-smiths used both techniques for

blade removals. |

|

CLICK ON PICTURE FOR LARGER IMAGE

CANAANEAN SICKLE BLADE SEGMENT

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This sickle blade segment

is identified as a product of Canaanean prismatic blade technology.

Sickle sheen along one serrated edge indicates that it was once used to

cut some type of plant fibers. Sickle blades were sometimes used to cut

on both edges. On a site in the Jordan Valley in Israel called Wadi

Fazael 2, it's reported that 32.6% of 43 sickle blades were reversed in

the haft and have bilateral sheen on their cutting edges. This blade

also appears to have traces of some type of material along one edge that

may be a hafting residue, such as bitumen. Bitumen is a solid or

semi-solid form of petroleum that is known to have been used to secure

sickle blades onto sickle handles. Most Canaanean blades have two

parallel ridges that extend down the length of the blade. The ridges are

formed along the edges of previously detached blades. This sickle blade

has a third dorsal ridge indicating a fourth blade was detached from the

core prior to the removal of this blade. Rosen writes that un-used

Canaanean blades average about 3/4 of an inch or 2 cm wide and they can

sometimes be greater than 5 7/8 inches (15 cm) long. This sickle blade

was made from a non-local fine grained brown flint. It measures 2 5/16

inches (5.9 cm) long and 1 1/16 inches (2.7 cm) wide. |

|

|

The economical use of some Canaanean sickle blades

is demonstrated by evidence of edge wear and sickle sheen on both

cutting edges. Rosen notes that up to 40% of the Canaanean blade

segments he observed were reversed in the haft. |

|

CLICK ON PICTURE FOR LARGER IMAGE

CANAANEAN SCRAPER

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This Canaanean scraper was sharpened into its current form from a

larger cortical (outer

core surface) flake. The original

outer cortex surface covers one side. This side and end-scraper is steeply

trimmed on three sides. Its most interesting characteristic is the

removal of the bulb of percussion. A single percussion flake cleanly

removed what was once the thickest area of the flake. This sickle

blade was made from a non-local chocolate colored fine grained

flint. It measures 5 1/8 inches (13 cm) long. |

|

|

Canaanean blades are generally long.

In fact, they are the longest that were produced by the four different

sickle blade manufacturing technologies that were in use at that time.

Canaanean blades are considered the

most efficient for the production of sickle blade segments because their

greater length could produce as many as three segments from one blade (Rosen: 1997). |

|

CLICK ON PICTURE FOR LARGER IMAGE

TABULAR SCRAPER

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

Tabular scrapers are

described as one of the lithic industries of the Early Bronze Age in the

Levant region. They are referred to as either tabular or fan scrapers

and they could be used as either scrapers or knives. Tabular scrapers were

made from large flat cortical (outer core surface)

flakes that were struck from flint nodules. Rosen describes them as

having outer cortex on virtually all of their dorsal surfaces. He also

explains that edge wear analysis has identified many of them as

butchering knives rather than scrapers. They may also have been used for

ritual purposes because some examples have incised designs on the cortex

and are found near temples and shrines. The suggestion is that they were

sometimes used in ritual sacrifice ceremonies.

Tabular scrapers can vary in size and

shape from fan, oval, round, elongate and irregular shapes. They range

in size from an average of 7 7/8 inches by 5 7/8 inches (20 cm by 15 cm)

up to 23 5/8 inches (60 cm). This example was made from a cortical flake

that was struck from a nodule of high quality fine grained flint. It

measures 5 3/4 inches (14.6 cm) long and 3 7/16 inches (8.8 cm) wide. |

|

|

There were four

different sickle blade production technologies in use in the Levant

region just after the end of the Neolithic period. Canaanean core

technology produced the highest quality blades. Another core and blade

technology is referred to as "non-Canaanean prismatic blades." This

technology produced small blades from cores that average between 2 3/8

inches (6 cm) to 3 1/8 inches (8 cm) long. These types of blades also

have a prism-like pattern on their dorsal surface. Another sickle blade

technology is described as "simple blade" and the fourth is termed

"flake-blade." |

|

CLICK ON PICTURE FOR LARGER IMAGE

TABULAR SCRAPER BLANK

EARLY BRONZE III PERIOD SITE

TELL HALIF, ISRAEL

2500 TO 2300 B.C.

This picture shows one side

of a thin tabular scraper flake that was found in a cache along with at

least nine Canaanean blades. The opposite surface of this cortical flake

is the outer cortex of the nodule core. This flake doesn't show any

heavy use wear along its edges and it's been described as a scraper

blank. But it does have some pressure

"nibbling" on a portion of its edge. This minor trimming might suggest a

use as a knife. This flake measures 5 9/16 inches (14.1 cm) long and 3

7/8 inches (9.8 cm) wide. |

|

|

Canaanean blade

technology was a successful manufacturing process that lasted in the

north and in the south Levant region for hundreds of years (Rosen: 1997,

59). The technology was used by craftsmen who traded their blades into

areas where quality lithic sources were not locally available. The demand

for quality products has always been a natural human trait that still

increases with each passing year. |

|

"REFERENCES"

1930, Neuville, "Notes de Prehistoire

Palestinienne," Journal of the Palestine Oriental Society 10.

1979, Hoffman, Michael A., "Egypt Before The Pharaohs, The

Prehistoric Foundations Of Egyptian Civilization," p. 88.

1996, Futato, Eugene M., "Early Bronze III Canaanean Blade/Scraper

Cores From Tell Halif, Israel," Retrieving The Past, Essays On

Archaeological Research And Methodology In Honor Of Gus W. Van Beek,

p. 61.

1997, Rosen, Steven A., "Lithics After The Stone Age," p. 44.

2000, John C. Whittaker, "The Ethnoarchaeology Of Threshing In

Cyprus,"

Near Eastern Archaeology, 63:2, p. 63.

2002, Lyons, Claire L., Papadopoulos, John K., "The Archaeology Of

Colonialism," p. 52.

2010, Bar, Shay & Winter, Haim,

"Canaanean Flint Blades In Chalcolithic Context And The Possible Onset

Of The Transition Of The Bronze Age: A Case Study From Fazael 2," Tel

Aviv, Vol. 37, pp. 33-34.

2012, Chabot, Jacques, & Pelegrin, Jacques, "Two Examples Of

Pressure Blade Production With A Lever: Recent Research From The

Southern Caucasus (Armenia) And Northern Mesopotamia (Syria and Iraq),"

The Emergence Of Pressure Blade Making; From Origin To Modern

Experimentation, pp. 181-198.

Personal Communication, Eugene M. Futato, 1992.

|

|

RECENT

LISTINGS HOME

ORDERING |