|

|

|

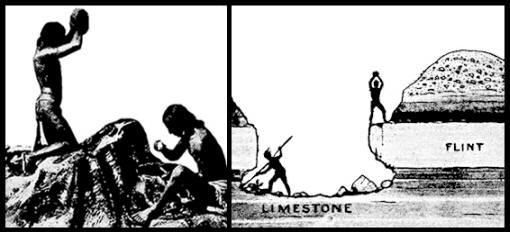

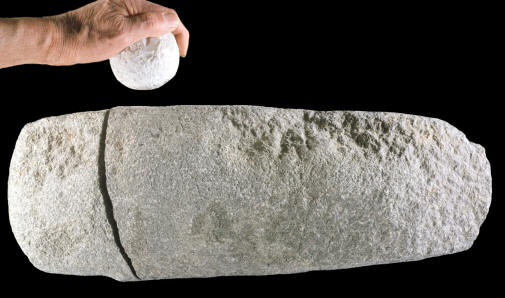

Hammerstones are found in a wide range of sizes and shapes. W. H. Holmes reports that on the quarry site at Flint Ridge Ohio, that "The hammerstones employed in the chipping work are very numerous. Some are bowlders picked up in the vicinity or brought from the neighboring streams while many are rough-shaped from tough portions of the flint. Most of the later are globular or discoidal in form, and many of the larger specimens used in breaking up the flint weigh as much as 50 pounds, while the smaller, with which the finer shaping work was done, are not larger than walnuts." He goes on to say that "A study of the rejectage (lithic debris) makes it plain, however, that the principal output of the shops consisted of leaf-shape blades ranging from 1 to 6 inches in length." |

|

|

|

|

Hammerstones have been in continuous use for as long as humans have been making stone tools. This includes the present day if you consider their use in Irian Jaya (New Guinea) where adzes are still being made with hard-hammers and whose ancestors have been making them continuously for thousands of years. In addition, there are also thousands of modern flintknappers, worldwide, that have turned the craft into a hobby and, in some cases, a vocation. |

|

|

Hammerstones are tools that can be compared to modern-day iron hammers, in-other-words, a tool that can be used to accomplish several different tasks. As applied to stone tool making, hammerstones have been used to reduce and shape different types of stones by striking off flakes and by pounding off granular particles. Striking off flakes will produce bifaces or blades and pounding off granular particles can produce ground stone axes, celts. adzes, etc. Stone hammers were also used to construct spectacular sculptures, such as the statues on Easter island or the two figures from Mound C at Etowah. They were also used in mining, for example as described by Wendell Bennett, on late Stone Age sites in northern Chile and northwestern Argentina: "Stone artifacts are numerous but none of them is especially distinctive. Most are of common utilitarian types, such as hammerstones, particularly heavy ones for mining copper----." |

|

|

|

|

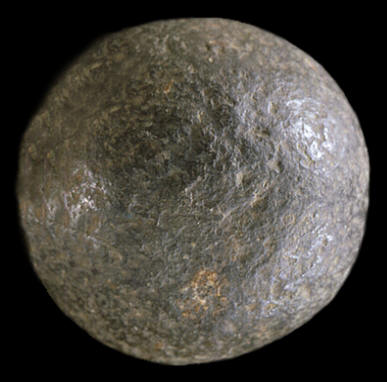

Hammerstones were made from a variety of different materials, such as granite, quartzite and other dense stones. A good percentage of them are simple unmodified water worn cobbles. An old description in 1898 by Williams describes them: "Wherever a brook rolled over the gravel beds, the Indian found it ready smoothed and shaped for his hand. On all his old camping grounds they may be collected in every sort of condition, from plain stone showing no marks of usage, through various stages of elaborate working, down to those that have been pounded to pieces." Some examples, such as the hammers used to make the Easter island statues were made of basalt that was flaked into shape by another hammerstone. Hammerstones can be identified by their battered appearance that differs from the stones' natural weather-worn state. The degree of battering varies from a very slight pitting on the edge to a complete reshaping of the surface. |

|

|

Hammerstones may not be the most impressive artifacts to look at. In fact, most of of them would go unnoticed by the general public. But if you consider their long history, no other tool that has been made and used by humans can compare to the important role they played in human development. |

|

|

"REFERENCES"

1898,

Williams, Frederick H., "Prehistoric Remains of the Tunxis Valley,

Hammer and Pit Stones," The American Archaeologist, vol. 2, part

4, pp. 87-88. |

|